Professional Experience

Junior Instrumentation Engineer

Almina, Aljustrel, Portugal

January 2025 - On going

Responsibilities:

- Reviewed and redmarked P&IDs for accuracy and updates;

- Analyzed and updated the instrument list, adding new instruments as per P&ID requirements;

- Developed cable lists for field instruments, ensuring proper connection and termination;

- Assisted in technical documentation and coordination with other engineering disciplines;

- Contributed to project planning and ensure compliance with industry standards.

I&C Technician

Northvolt Ett, Skellefteå, Sweden

July 2023 - On going

Responsibilities:

- Conducted comprehensive testing and commissioning activities for a wide range of instruments and equipment within HVAC, BMS, and UMS systems.

- Evaluated and validated transmitters, valves, pumps, and fire alarms to ensure compliance with industry standards and optimal functionality.

- Utilized troubleshooting skills to diagnose and resolve issues promptly, minimizing downtime and enhancing operational efficiency.

- Proficiently annotated loop diagrams and executed corrections using AutoCAD, ensuring seamless integration and alignment with project specifications.

- Generated detailed Instrument Test Reports, maintaining meticulous documentation for future reference and regulatory compliance.

- Reviewed and redlined Control Narratives for HVAC systems, identifying and rectifying discrepancies to enhance system performance and reliability.

- Demonstrated expertise in Chilled Water Supply and Distribution systems, including the application of Variable Frequency Drives (VFDs) for pump control.

- Executed testing and commissioning procedures for Chillers, assessing performance and functionality to optimize operation and energy efficiency.

- Played a key role in the commissioning of Air Handling Units, ensuring system integrity and functionality while aligning control narratives with project requirements and industry standards.

Interships

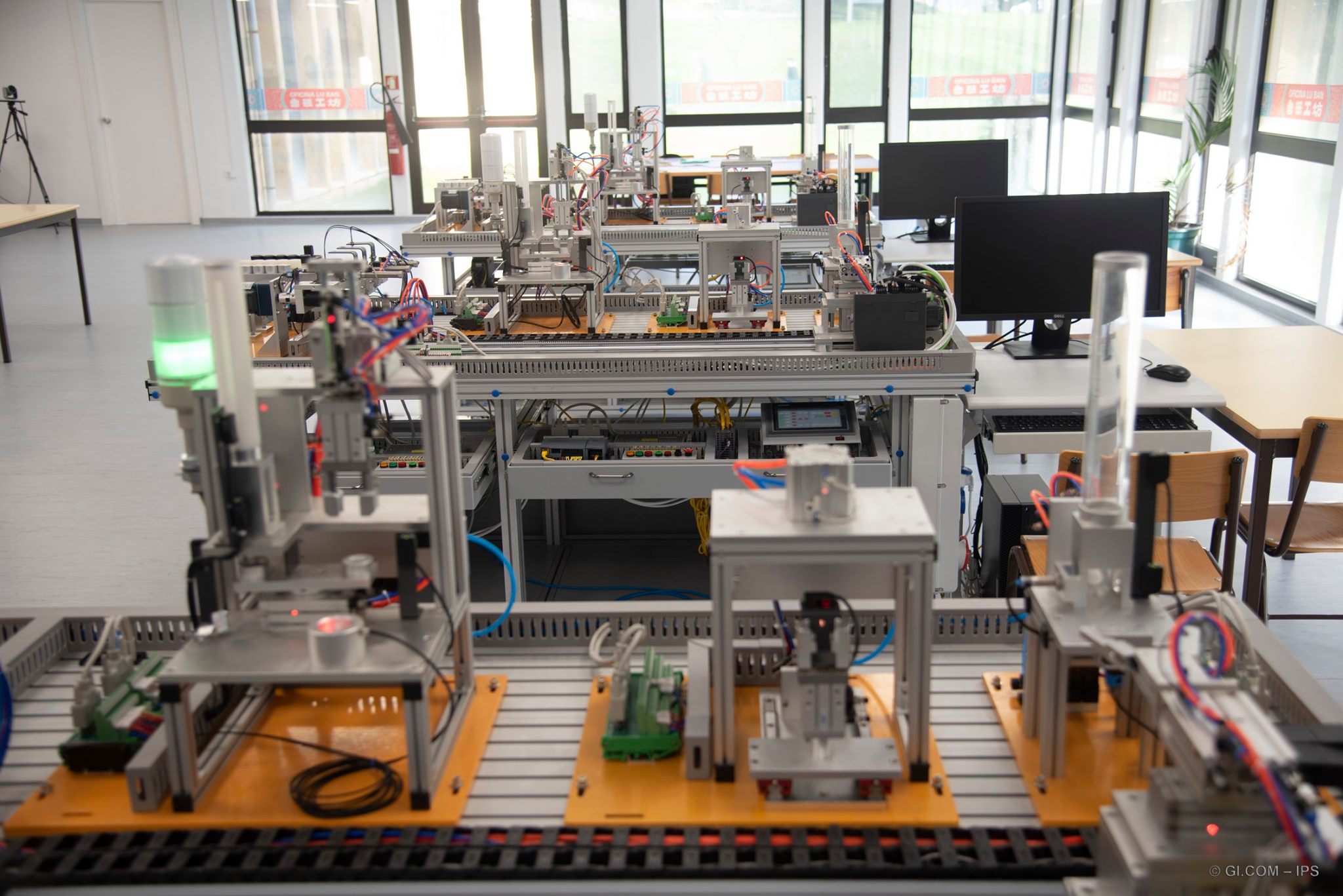

Automation Technician

Luban Workshop, Setúbal, Portugal

March 2020 - August 2020

During my internship at Luban workshop, I had the opportunity to gain practical experience and contribute to various aspects of automation systems. Here are some key responsibilities and achievements:

- Programmed an Automatic Process Line using TIA-PORTAL software, effectively implementing control algorithms, and ensuring seamless coordination of multiple components.

- Installed motors and equipment on assembly lines, meticulously configuring and verifying their functionality to ensure optimal performance and adherence to safety standards.

- Programmed systems to control and monitor the performance of installed motors and equipment, leveraging my technical knowledge to develop efficient and reliable automation solutions.

- Connected communication and signaling cables to various sensors and actuators, meticulously ensuring accurate data transmission and proper operation of individual components.

- Executed startup procedures to initiate and verify the performance of installed systems, meticulously troubleshooting and fine-tuning parameters to optimize overall system functionality.

Throughout my internship, I gained invaluable hands-on experience in programming, assembly, installation, and commissioning of automation systems. This experience not only enhanced my technical skills but also provided me with a deep understanding of the practical application of automation principles.

Electrician Technician

TAP - Maintenance & Engineering, Lisbon, Portugal

April 2018 - June 2018

During my role as a Maintenance Technician, I gained valuable experience working with turbofan engines and ensuring their optimal performance. Some key responsibilities and accomplishments include:

- Conducted maintenance of electrical cables and fire sensors for turbofan engines, thoroughly inspecting and repairing any faults to ensure the safety and reliability of the engines.

- Performed testing of turbofan engines in a dedicated test bench, diligently conducting continuity and insulation tests to assess the electrical integrity and overall functionality of the engines.

- Ensured comprehensive documentation by diligently completing test reports to keep track of all testing procedures and quality assessments. This careful record-keeping was vital for maintaining a thorough understanding of the testing processes and ensuring the highest standards of quality.

These experience provided me with a deep understanding of the intricacies of turbofan engines and allowed me to develop strong technical skills in maintenance and testing procedures. I gained valuable insights into the importance of thorough documentation and quality assurance in maintaining the systems.